Some deliveries may take a little longer than usual due to regional shipping conditions.

Customer Services

Copyright © 2025 Desertcart Holdings Limited

🛠️ Work smarter, not harder — your ultimate portable powerhouse!

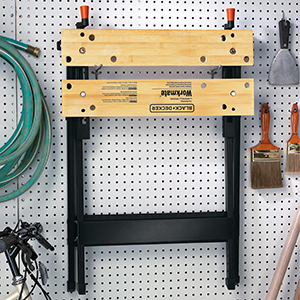

The BLACK+DECKER Workmate WM125 is a portable workbench engineered for professionals and DIYers alike, boasting a robust 350-pound capacity supported by a durable steel frame and warp-resistant wooden jaws. Its lightweight 15-pound design folds flat for easy storage and transport, while four adjustable swivel pegs provide versatile clamping for irregular materials. Non-slip feet ensure stability, making it the go-to compact workbench for efficient, on-the-go craftsmanship.

| ASIN | B000077CQ0 |

| Assembly Required | Yes |

| Base Type | Casters |

| Batteries Included? | No |

| Batteries Required? | No |

| Best Sellers Rank | #276,530 in Tools & Home Improvement ( See Top 100 in Tools & Home Improvement ) #238 in Workbenches |

| Brand | BLACK+DECKER |

| Color | Black |

| Customer Reviews | 4.3 4.3 out of 5 stars (15,066) |

| Date First Available | October 15, 2002 |

| Finish | Brushed |

| Finish Type | Brushed |

| Frame Material | Alloy Steel |

| Global Trade Identification Number | 00028877364858 |

| Head Style | Flat |

| Included Components | WM125 Project Center | (4) Swivel Pegs |

| Is Discontinued By Manufacturer | No |

| Item Package Quantity | 1 |

| Item Weight | 14.85 pounds |

| Item model number | WM125 |

| Load Capacity | 350 pound |

| Manufacturer | BLACK+DECKER |

| Material | Steel,Wood |

| Maximum Weight Capacity | 350 Pounds |

| Measurement System | Metric |

| Minimum Height | 12.7 Centimeters |

| Part Number | WM125 |

| Pattern | Solid |

| Power Source | hand_powered |

| Product Dimensions | 5"D x 5"W x 35"H |

| Shape | Rectangular |

| Size | One Size |

| Special Features | Lightweight |

| Style | Portable Workbench |

| Torque | 1400 Inch Pounds |

| UPC | 028877364858 |

| Warranty Description | 2 year warranty. |

U**E

Good deal, instructions useless, watch the video (There are several good ones) Tips on assembly!

Note: I'm a 63 yr old Handy-Lady, and well used to getting my hands dirty, and make furniture and other woodworking projects. Like many people I was wary of getting this workbench set up. I actually bought this in May and left it till I needed it - September 9 - to assemble it. I forgot the return window for Amazon had closed, so I was really nervous when I examined the box, which had obviously been opened and resealed. And even more so when I found one of the plastic bags of parts was opened. But, I looked up the Black and Decker assembly video for the WB125 and setup my iPad to watch as I assembled it First - and I am one of those people - I arranged all the parts and hardware exactly as shown in the video, and was pleased that nothing was missing. TIP #1: Make sure you have the 2 cross-braces identified as the shorter one goes on the inside legs, the longer one on the outside legs - the holes won't line up if you make the same mistake I did. TIP #2: Yes! Use locking washers - 8 x M6 lock washers - on these cross-brace attachments to make sure it is as sturdy as possible TIP #3: There are 4 slides included for the vise. These are actually 2 sets of 2 and are not identical. The first set have a protruding knob which fits in the hole in the metal top of the bench. This set is the one used to attached the non-moving part of the vise - the one without the printed logo and product name on it. Everything else went smoothly - watching the video carefully - and I even used the Roll Pins to attach the handles. I had bought - upon the advice of a number of reviewers - but the Roll Pins - with a little force, went through OK. Tip #4: I attached the feet, which fitted well, but also used Flex-Glue, since the feet are flexible plastic. I literally just finished the setup, so I can't say whether this was a good idea, but it seemed logical to me. Once assembled it seems very sturdy and - I used to have one of the original 1970's versions - not quite as solid as the original, but good enough for my home projects. At $40 (incl. tax - and it's now even cheaper) I am very pleased with the workbench. VIDEOS: Search YouTube for WB125 Assembly and you should get the one from the Black and Decker Product Manager. But also search for "How To Put Together A Black+Decker WorkMate 125 Portable Workbench" by user, 'Help at my Home'. He runs through some of the confusing aspects of assembly and the various parts and pieces that might get your frustrated. _______ Hammer On!! -Kim

M**S

Assembly required, but works as advertised

ASSEMBLY - I hate assembling stuff! It took me over an hour to assemble. I ordered two sawhorses and even though I had successfully finished one it still took me almost 45 minutes to finish the second one. I can't say the instructions are wrong as they are "technically" correct. But parts are not labeled or described well and assembly images are not always clear. I was searching for a nut driver in the garage and then later figured out that a plastic nut driver was provided in the bag of parts but wasn't identified as such in the instructions. Sometimes it's like looking at a map where someone has decided that west should point to the top of the map (by the way, maps normally are oriented with north to the top). USAGE - These sawhorses are very sturdy. I haven't tested out their claimed capacity of 350lb (160kg) but they seem like they should be handle that much weight. The vise feature works nicely for holding items. There are some removable plastic inserts on the top that can be used to provide stoppage points (I think of them as small walls) so items can be positioned in a more steady manner, however, I find using separate clamps more intuitive. All in all, I would probably buy these again if I needed more sawhorses.

J**N

Good Product, But An Ordeal to Assemble

I like that the product folds up and is very versatile, and can be used like a sawhorse for tasks like cutting up an old fence to repurpose wood. Assembly, however, was a half-day ordeal because the printed instructions were woefully bad and even left out a crucial washer (spacer) in the parts list for the very first assembly step. The Black and Decker and independent videos, recommended by some reviewers, were less bad, and made assembly possible with some improvisation. I will explain in a little more detail, as the videos seemed to cheat (skipping over steps to show things as finished), and it can be tempting to just return the item in frustration, or throw it out the nearest window into a trash bin. The printed instructions and videos say you need the little plastic bolt tightener provided, and it works great. They also tell you to use a hammer and flat-head screw driver, but the product uses phillips screws and a rubber mallet will be a better choice to bang things into place without causing damage. Unless you have very strong hands like the guy in the video, you will need a pliers and mallet to assemble the handle. There is one step at the very end where you need the hammer to bang a pin into the handle, but they do not mention that it helps to have pliers to squeeze the tip of the pin so that it fits. The Black and Decker video claims at the outset to show you every step, but it lies. The video goes too fast and skips steps. I found it best to download a copy of the video, and then refer back to it each step of the assembly, and then disassemble and reassemble each step of the assembly to get things right. Makes things slow. I was tempted to give the product 3 stars or less, on account of the difficult assembly. The printed instructions omit the black washer from the parts list, which guarantees having to disassemble step one and start over after watching the video, where the washer is called a “spacer”. I had to freeze the video and replay it a few times, as the spacer flashes by in a nano-second and it is hard to see where it goes. In fact, every step of the way I had to freeze the video to see how the parts were placed, as nothing is marked and it is easy to get things turned around. When I got to the handles which go onto a metal sliding rod, one of the independent videos recommended disassembly because the Black and Decker video assembly just did not work. Indeed, I found this out for myself. An orange plastic knob just pops into the black handle near the end of the B&D video; but I needed pliers to compress the end of the orange knob and a rubber mallet to hammer it in safely. This after a disassembly to remove the sliding metal rod, to prevent it spinning around (the videos do a cheat on this, or perhaps have a second person out of sight holding it). The video at the very end also shows hammering a pin into the handle, which is just not possible (at least for me) because the rod will spin and you cannot line up the holes if it is assembled first. So, I used a pliers to squeeze the tip of the pin and then held down the handle and attached metal rod on a work table so it would not spin while I hammered in the metal pin. Then I used a rubber mallet to gently hammer the handle and attached metal rod backwards from the front of the assembly to the back. It is not meant to be done that way, but one of the independent videos found that was the only way they could assemble it, too. Improvisation every step of the way. An ordeal, but the competing assembled products were rated as junk by most reviewers. So...

N**I

The workbench arrived missing two bolts. I was unable to assemble it without these two important items. Efforts to obtain them came to zilch in spite of my best efforts. So item was returned.

S**D

Collapsable and the vice feature is great. Great value for money too. If your making anything at home that needs a vice and a flat surface you should buy this, very convenient.

J**L

Bonne qualité, très pratique pour les petits bricollages

J**D

Easy to use, slim when folded - so easy to store, sufficiently robust for home use, light enough to lift and carry.

M**Y

Excellent product. Don’t let the hard to grasp assembly instructions put you off. For that one time set up. Simply type the make into you tube & watch how to put it together.

Trustpilot

2 weeks ago

2 weeks ago