Customer Services

🚀 Elevate Your Printing Game with Voxelab!

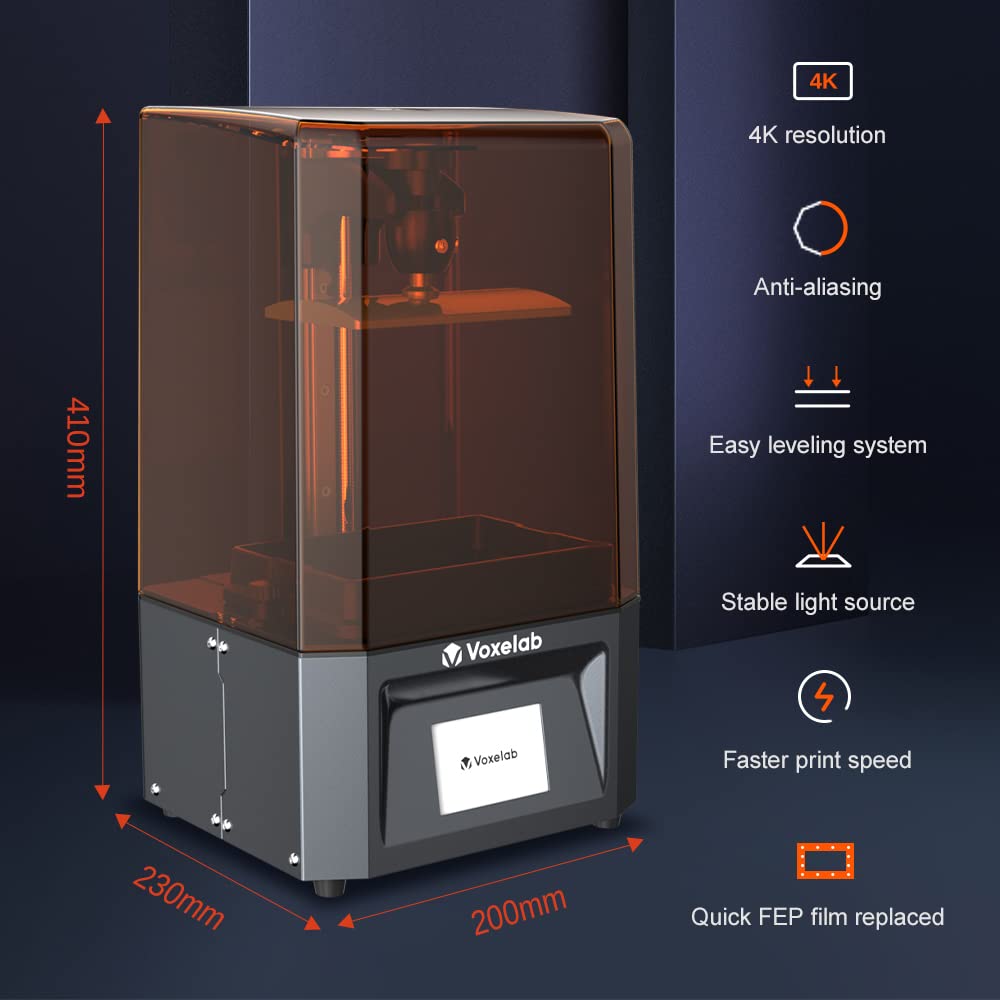

The VOXELAB Resin 3D Printer Proxima features a 4K monochrome LCD screen for high-definition printing, an upgraded UV LED light source for even light distribution, and full grayscale anti-aliasing for intricate details. With a print speed increase of 50% and a compact design, this printer is perfect for professionals seeking precision and efficiency. Plus, enjoy peace of mind with lifetime technical support and a one-year warranty.

J**E

Slow Service but Good Follow up.

UPDATE: I was able to use the FEP Film that I bought for this machine and it works like a champ again. Still a little irritated I was sent the wrong thing, but they did respond slowly that they were sending me the correct FEP. I have revised my Feedback based on this service update.I bought this machine and I loved it. it was awesome and I have printed a lot of minis in the 2 months that I have had it. As expected, I needed to change out the FEP after so much use an I ordered the product from the manufacturer. It was totally the wrong product and I have have sent two queries to them to see about getting the correct FEP for the vat. No Response. I have tried using two of the 10 films that I bought for an EXORBITANT amount of money and just tried to make them work. Failures. I cannot get the printer to work like it once did once I have changed out the FEP.I feel Cheated. I don't want to spend another 65 bucks for 10 FEP films that may or my not be correct and I cannot bet the Chinese makers of this product to give a crap.I recommend that if you want a 3D Printer. Spend a little extra and make sure that you can by parts and material on Amazon or at least in stock in the US. This is beyond ridiculous, sad, and frustrating. I love the printer but not the company or the items needed to make it a working machine. At this point, it is a paperweight.

R**R

Welcome to the World of 3D Printing

I'd considered getting a 3D Printer before, but could never justify it. Then I got into partworks modeling, and needed some way to print some parts for a model I'm going to start working on (and putting up on my YouTube channel if you want to take a look at that [search for The Model Gamer and you'll get right into it]). So I decided to take the plunge. I immediately decided to get a resin printer because I didn't want that line look from standard filament printers. I wanted my pieces to be detailed and clean without sanding, because, when working with fine details, sanding is not an idea.This printer was highly reviewed, and seemed very intuitive to use. So I got it. And tried to use it. And had problems. The pieces weren't sticking to the plate. But, after a quick search, I solved my problem. To put it easily: when setting up the print, you want to make the first several layers cure LONGER than your normal layers. I have my settings to where the first 8 layers have a cure time of 60 seconds, and the rest typically between 10-12 second per layer.It's necessary to understand how this printer works. Basically, each layer is made by UV light from the bottom curing the resin in a particular way to match the shape of whatever it is you're printing. If those first layers of resin don't have time to really cure onto the plate, it's not going to work right. Once you figure it out, though, you'll be printing all sorts of things. Eventually, you're going to find the Thingiverse rabbit hole and start going nuts.As for the quality, it's incredible. The parts I've painted come out with very nice details. I actually printed a model of the Titanic out, and you could see fine lines in the decks, windows in the hull...you could even clearly see the propellers. And this is on a model roughly 5-6" long. It's so satisfying to see the finer details come through so effectively.Now, I've had a couple of problems, but I chalk that up to new user stuff than any faults of the printer. I was trying to really get a lot of detail into a model and dialed up the per layer cure time to something ridiculous (think it was, like, 20 seconds per layer). DO NOT DO THIS! I think I wound up having the UV light on TOO long and it basically cured the piece more to the vat than to the plate. And then, when I tried scraping it off, it was so stuck on there, it actually ripped the film on the vat and got resin all over my LCD screen.Now, this leads to the next thing: ease of maintenance. And let me tell you, this is pretty easy. Replacing the FEP film is intuitive and simple. And I even had to replace the LCD screen, which they make VERY easy to do. Just be sure to look up how to change it out, or you might start unbolting the wrong thing. Also, make sure you get the setup to work exactly. You want a piece of paper to be slightly difficult to get out when pulling during calibration. Not impossible, and not easy, just a bit more difficult. You'll know it when you feel it.Also, with this printer, you NEED a wash and cure station, which I also bought. You'll also need to get yourself some isopropyl alcohol to clean your pieces and your unit. This is NOT a grab-and-go printer. There are other things you'll need to buy before you're off to the races. But when you do...I promise, you're going to have a lot of fun making things.

A**Y

It works well and is built like a tank!

I own eight extrusion 3D printers and this is my first UV resin printer and I am very impressed with the build quality and print quality right out of the box.There is only the printing adhesion surface platform to the digital color screen imager (this makes the reverse of the image to print layer by layer by allowing and blocking UV light from being exposed to the UV sensitive resin in the resin tank) which is like setting a Z height with the thickness of a sheet of paper. Minus the exposure time lengths needed to properly expose the resin, there really isn’t much to do to print fine quality items.I print at about 1” per hour, The printer only worries about raising the layer height with each exposure because a 1” tall item being one only or ten copies will print at the same speed because it’s about the layer heights only.This is not a mono screen and I have not seen any modifications for this as of yet so it’s not the fastest printer out there.Overall I am very pleased and it’s the best bang for your buck out there at least than $150 and make sure to shake your resin well, clean up any spills with IPA quickly and keep the clear FEP film clean and scratch free or you might miss a small part of your print like in my photo. A good way to remove the mishap stuck to the FEP film is to clean the FEP from the original resin with Isopropal Alcohol and then with really clean fingers or even a micro fiber cloth, push the error that is stuck to the FEP film with the tip of your finger and it will begin to lift off of the FEP film. Do you go back and forth with the provided plastic scraper or you will damage your FEP film. It is good to always have extra FEP film on hand as it is easy to replace.I use the enclosed plastic scraper to wipe the build plate top and some of the bottom and sides to drip as much of the resin back into the tank as possible. It is also a good idea to filter your resin every once in a while as any settling particles that have lightly hardened will only get in the way of a pixel being exposed to the UV light to your build plate or item being printed.Wear those gloves or your fingers will turn to hardened plastic and it is a toxic chemical anyways so its better to work / play safely.

L**A

Stampa 3d facile e bellissima.

Premesso che sono alle prime armi devo dire che contrariamente a quanto visto online sono rimasto molto contento della facilità di settaggio e di utilizzo. Il settaggio risulta già impostato perfettamente di fabbrica e lo schermo risponde benissimo hai comandi. I materiali sono molto buoni ed il vano porta resina è in metallo. Se a tutto aggiungiamo una lente che permette una risoluzione 4k, devo dire che la stampante è davvero buona, almeno x chi come me è agli inizi. La stampante ha inoltre un software proprietario di facile utilizzo con impostazioni preimpostate installato nella chiavetta USB in dotazione insieme alle istruzioni in formato pdf. In finale ottimo prodotto facile utilizzo.

R**F

Amazing performance, High Quality a perfect entry /intermediate SLA Printer

The media could not be loaded. I was looking for my first SLA resin printer and already had some choices that I was researching. This was my first experience with a resin printer but I have had some experience with FDM printers and I thought this would be the next step. I was almost ready to buy one of the more known brands (Anycubic/Elegoo) when I found out about the Voxelab Polaris. It wasn't a major player yet in the entry level SLA printers, but I did some research and found out it was a subsidiary of FlashForge (very established 3d printer company). The printer is an amazing value for under $300 dollars (as of this writing it is $259 on Amazon.ca). All the features you would want. Easy to operate, comes with all you need to start printing (except the resin), compatible with almost all the 405nm resins on the market, 2k resolution lcd screen, metal resin container and other quality features. Be wary of some entry level printers as they only have a 850x480 resolution screen (lower resolution prints).I ordered the Voxelab and it came within 2 days via Prime Shipping. Very well packaged to ensure you get your printer undamaged. You get a couple of extras with the printer to make sure you have everything you need for your first print. Metal and plastic scrapers, resin strainer, nitrile gloves, allen keys and extra screws, Sandisk usb drive with all the software and instructions. I ordered some resin (separately) and started a small print to really test the resolution. If your not familar with SLA printing watch some videos on YT as there are precautions you must take to ensure safe operation as the resin can be toxic to your skin and environment. The Voxelab Polaris comes with VoxelPrint and Chitubox software slicers to help transform your 3d projects to a file that the Polaris can use. Easy to use software if your already familiar with 3d slicers. I loaded up a version of the Formlabs "Twisted Rook", which can be a challenging print. After 2 hours I followed the proper rinsing and curing of the model and I was impressed. I could not get this kind of detail and smoothness from a FDM printer. I scaled the print down so I could see if it could still get all the detail on a smaller print. I am convinced the 2k resolution allowed me to get such great detail from a small print (see examples). I am sure this printer will be able to handle all the high resolution printing I have in mind.If your looking for a high quality, high resolution, easy to use SLA 3d printer with a great price ...the Voxelab Polaris is an excellent choice and I would easily give it 5 stars!!!

A**R

First time 3D printing.

I have no experience with 3D printing and found the Voxelab Proxima simple to set up (leveling) and print. My first print went off without a problem. Clean up is easy enough. Would recommend.

B**N

Not a very good product, not very good support.

Bought this as my first SLA 3D printer. Raving YouTube reviews, Reddit, Amazon, you get it. What a mistake.It's cool looking, but that's about where my fun stopped.Bought the Proxima with their branded black resin. The test deer printed OK, not great. Second print, failed. Third print, failed. Fourth prin...you get the idea. At first I thought it was me, I researched like crazy and learned all the tricks of rotating parts, adding MORE STRUTS. Nothing worked. I printed some resin tests to 'dial-in' the exposure. Nope, even those stuck to the FEP.Everything sticks to the FEP. Who can blame 'em look at the FEP from the 'factory'. There's flakes of aluminum under the FEP between the frame. It looks like it was wiped with sandpaper. The FEP formed a hole on the second use due to the sticking. I contacted their support and they told me to be more careful.... I replaced the FEP with the extra from the box. Guess what, everything sticks. Even followed a video about tuning the FEP(?) I don't know. I was willing to try anything.Their manual is a dumpster fire. The gloves in the kit are for children. The build plate would never get perfectly level. I can only assume its from that awful ball/socket thing for the plate. The power adapter plug doesn't quite fit right, heh lost a print on that too. They include their own slicing software, VoxelPrint. It does the job, but it isn't flashy. They also support Chitubox, but good luck trying to get the correct settings in there. They have a profile you can import but Chitubox also includes support. Each seem to have different parameters.Amazon was of little to no help. Three 'agents' later (seemed like bots) and I was offered $20 refund for my troubles. $20 cannot buy new FEP sheets. They can't send a replacement because it's only fulfilled by them.I wasted time, money, resin, alcohol, gloves, etc. I am returning this device. Perhaps the world isn't ready for a $280CAD SLA Printer.===================Update 4/22/21I've been in off/on contact with the parent company FlashForge regarding this product. They offered me $50 off another purchase. I'm not sure where Amazon or FlashForge/Voxelabs gets the idea that $20 and $50 is a deal breaker, but sheesh. I STILL couldn't buy more FEP sheets for $50 let alone the $100+ I wasted on supplies. FlashForge said that the Voxelabs support employee was 'new' and didn't know how to handle my issue. So of course the default answer for them is to blame the user. Thanks for that.I've since returned the printer and got about 25% returns on the left over resin. I'm out my time and money for this junk. Seriously avoid, don't fall for the 'influencer' reviews.I bought an Ender 3 from Creality and haven't looked back. Someday I'll venture into resin printing again, but not using a FlashForge or Voxelabs product.

E**O

Stampa a resina, tutt'altro livello

Premetto che e' la mia prima stampante a resina, provengo da parecchie stampanti fdm, quindi magari non sono super esperto in campo resina. Arriva in una scatola ben imballata, a me e' arrivata prima del previsto, con all'interno vari accessori, ma non la resina per provarla, quindi va subito comprata insieme alla stampante. Inoltre forniscono una pendrive, ricca di contenuti, come guide per l'uso, per la sostituzione del display.... Appena arrivata, l'ho tirata fuori dalla scatola, ho livellato il piatto, roba da 2 minuti come in tutte le stampanti a resina, e ho fatto partire la prima stampa, il cervo. Devo dire che sono rimasto sorpreso dalla qualita' dato che provenivo da una fdm, ma ancora non ero soddisfatto al 100%, cosi decido di utilizzare chitubox come software di slicing e metto in stampa l'anello a corona. E devo dire che nonostante le piccole dimensioni, si riescono a notare tutti i dettagli. Ovviamente la stampa a resina ha anche i suoi svantaggi, specialmente dopo che si ha terminato una stampa. Ma appunto questo e' un difetto che fa parte dell'hobby e che e' proprietario di tutte le stampanti. Per i vari test ho preso della resina elegoo, grigia, quella classica. Che dire, di certo la consiglio, specialmente a chi ha altre stampanti, magari fdm e vuole provare la resina, tutt'altro mondo. Non posso fare purtroppo paragoni con altre stampanti a resina dato che e' l'unica che possiedo. Passando infine a cosa si potrebbe migliorare, bhe una guarnizione che isoli meglio il coperchio non guasterebbe, ma si risolve con un paio di euro, io ho usato della guaina per le finestre con un po' di nastro isolante

Trustpilot

1 day ago

5 days ago