Cutting Edge Performance ✂️

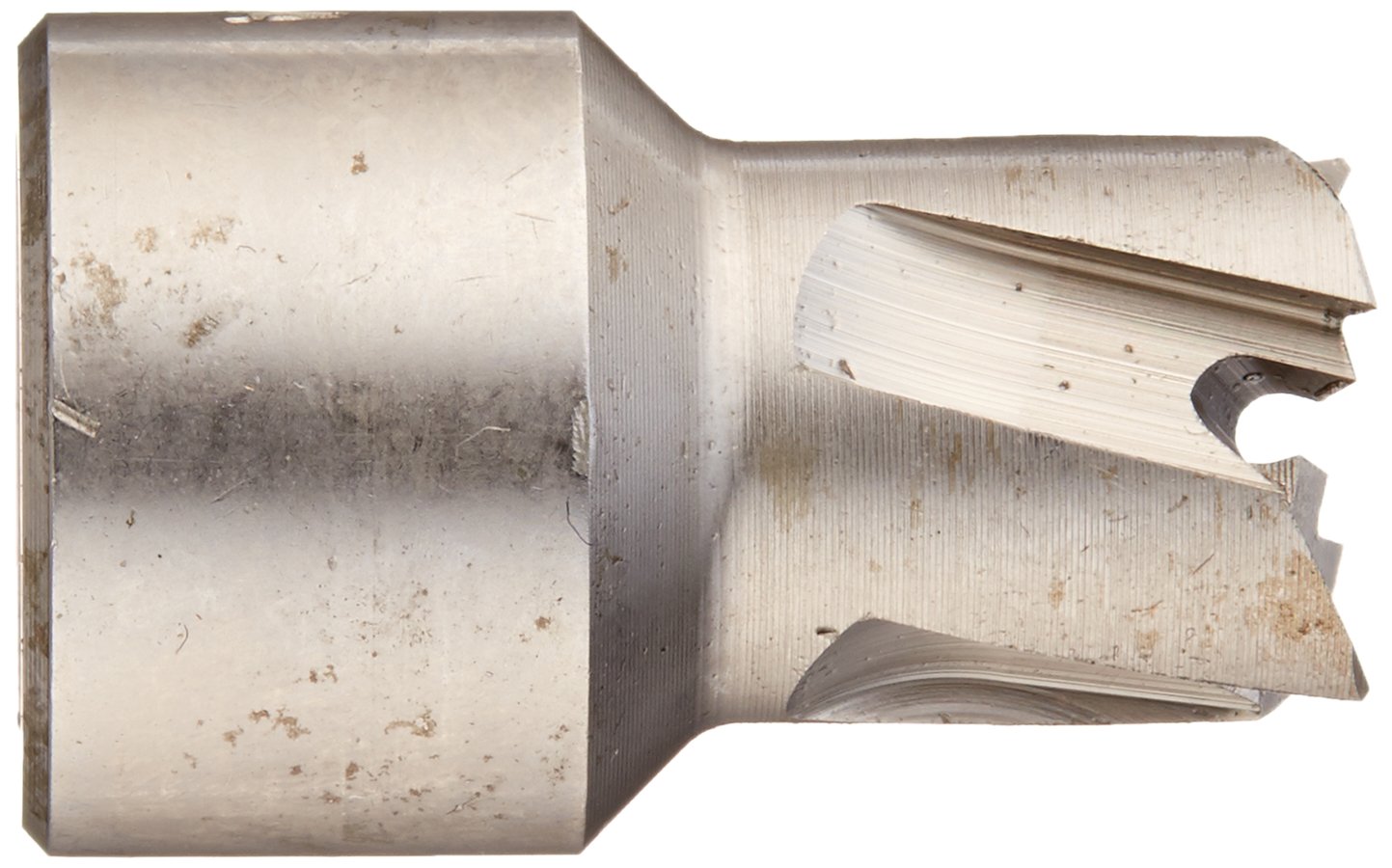

The Blair 11108-3 Cutter is a high-quality, award-winning tool designed for professionals. With a cutting width of 3/8 in and state-of-the-art technology, it meets the demands of modern users while ensuring precision and versatility for various applications.

W**T

The slower you go, the faster you'll get there.

I had first purchased the 11094 tool to remove some quarter panels a few years back. I used it again last year for another project. The first cutter successfully removed 5 quarter panels in all before I realized it just didn't seem to be up to the task anymore. That was probably 120 spot welds in all, most of which were in less than ideal angles as I was working around wheel wells and body components.I also wasn't very prudent with my drill speeds and rarely used a cutting lubricant.So, I just ordered this set of cutters, and a stick of lube to remove some 1960s spot welds. I'm watching the speed on the drill this time and it is just a joy to work with. Use a good center punch and try to stay square as possible while maintaining good body control.

I**E

Nice

Nice

D**S

Expensive cutter heads...

...and worth every penny! Used at low speed (<500RPM) with light pressure, this style of spot weld cutter is just amazing compared to the double-ended junk sold at most parts stores & paint jobbers. They will not fit the same arbors as those double-ended cutters, you need the specific Rotabroach arbor (the full kit is Blair #11096). I removed the original roof from my car with one cutting bit--that's almost 150 spot welds in all. Impressive. Don't spin these too fast or push too hard, just let the cutter do its thing. If you hit a wire weld it will shear a tooth or two off, so check your area carefully. You'll get a lot of use out of each bit.

A**.

Not consistant bits

When they work they are great, one bit would cut 8-10 spot welds and another barely last after 1!!I used cutting oils to help prolong and nothing no change. I am drilling 1018 20ga sheet metal welds on a car so nothing crazy and still these bits are horrible. You start spending more money on bits than you do the project your working on or installing you know it bad. Just hope you get a good batch of bits....

B**E

Awesome spot weld cutters

I've had the old Rotabroach "Blair" spot weld cutter for years and have broken only two bits in that time period. I'm not a professional body man so they aren't used that often but i've done some pretty major repairs such as rocker panels, quarter panels, patch panels etc. As long as you take your time use a lubricant and keep the bit straight these things seem to go forever.

M**N

Very sharp and aggressive

Very sharp and aggressive. Second weld in it jumped around, broke 3 cutters off. Stil drilled a whole floor pan out of a Chevy truck bed and half of the replacement bed floor. It was cutting fine still, but I let it walk and broke the last tooth. Replaced with a new cutter, and practiced better drilling technique. That one has done over 100 spot welds, and still cuts great.

T**D

Better than a Drill

These cutters are pretty good, better than the other style. However, they could be better. I found that the drill bit in the cutter doesn't do much drilling and will skip around. To get these to work, I suggest drilling a pilot divot. Also, the 3 that came with my kit didn't go dull but broke off one or multiple cutters making them useless. Even with cutting fluid. They can be sharpened and used again but the blades cracking off was a pain.

C**T

Works Great

I bought for stock to replace the ones in my kit when they eventually wear out. I have only used them for a few months before winter hit but they worked well and better then Harbor Freight tool that is a double sided saw hole design. Which I could not unscrew to flip the head over but the Blair's don't jam. Mike Solberg would say "you buy junk you ride junk". Blair lube works great too.

Trustpilot

4 days ago

5 days ago