Customer Services

Copyright © 2025 Desertcart Holdings Limited

Desert Online General Trading LLC

Dubai, United Arab Emirates

🚀 Elevate Your Prints with Precision and Power!

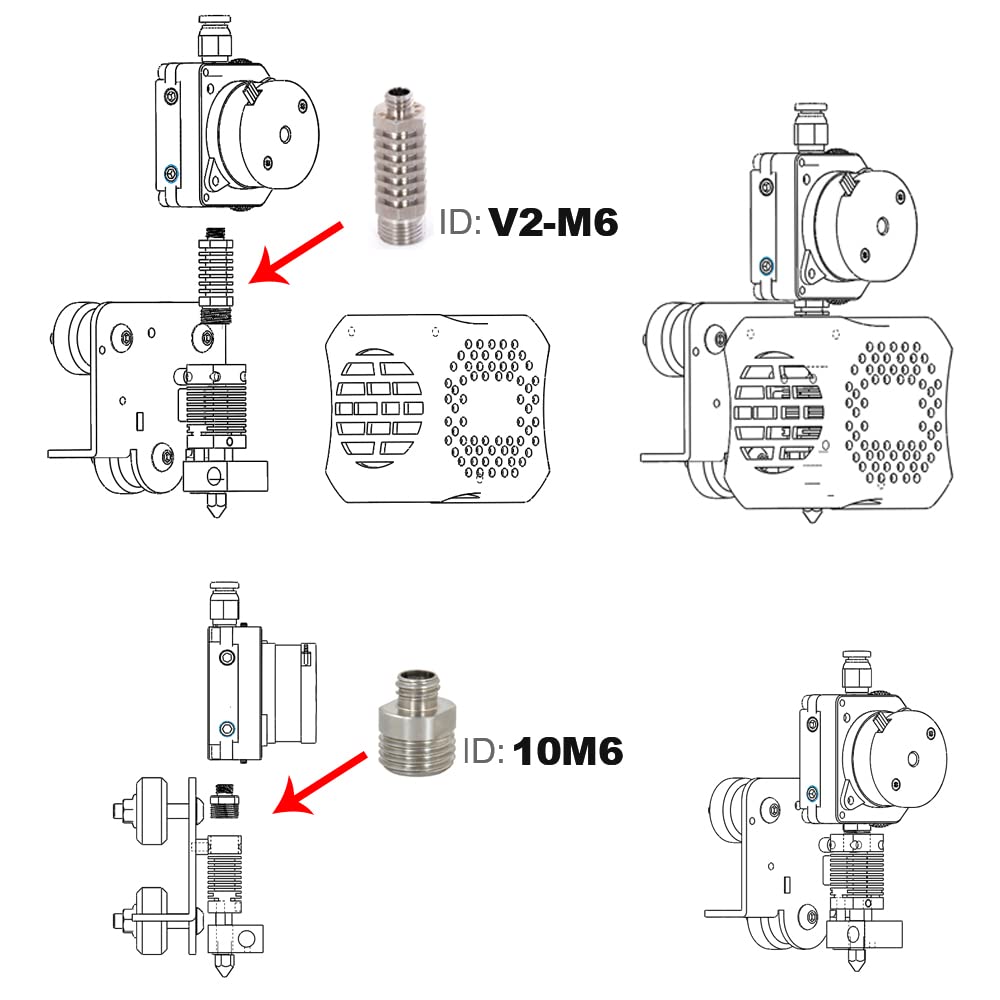

The Newest Upgrade Extruder OMG DM1 is a cutting-edge dual drive metal extruder designed for 3D printers, featuring enhanced stability, durability, and compatibility with various filament types. With its innovative design and high-quality materials, it promises to revolutionize your 3D printing experience.

| Manufacturer | NTF |

| Part number | OMGDM1 |

| Item Weight | 314 g |

| Package Dimensions | 17.3 x 14.6 x 4.8 cm; 314 g |

| Manufacturer reference | OMGDM1 |

| Color | Grey |

| Batteries Included? | No |

| Batteries Required? | No |

S**L

Great Quality - High Performance

This Dual Gear Drive is actually a very well thought out design.* Great Quality*Light weight* Dual Gear Direct DriveThe Good:=========1. I liked the heat vanes that are designed to rapidly dissapate any excess heat coming up from the hot end.2. Easy to assemble.3. Affordable price.4. Easy to set up and calibrate. (ESTEP SET TO 690)(I did not have to Auto tume my PID settings at all on my Ender 3 Pro5. Extruder worked perfectly tuned on the 690 E Step setting on my calibration 100mm filament test.-------------------------------------------------------------------------------------------------------The Not So Good===============* Vague instructions - outdated.* No List of which parts suit which model of 3d Printer.* No pictures to show the correct orientation of the unit to work correctly (AS shown in my photos)* No Instructions to tell you to mount the stepper motor with the wires Facing up and at 10 oclock position to stop cables getting jammed in the bed and on X stepper motor.* No Alignment dowels to set correct back lash on gears (the two faces are very loose and you have to just guess a bit of backlash as no guidence is given).* Video links only showed old unit version and not the new parts and how to adjust it and how to set up the internal Bowden Tube.I fitted with a Bi Metallic Heat Break (Titanium and Copper) to allow hotter materials to print.Youtube "Westy Crypto" Channel for my overall reviews

M**W

Bring on the flex!

Purchased this so I could print TPU (flexible filament). Had to an issue with the motor not working but the seller sent a solution and now it's printing great. Very lite weight and well made. It's a great upgrade for my Ender 3 Pro.

W**L

Good. But could be much better for the price

I’m using this on an Ender 3 V2 with dual z upgrade. I bought this based on the review on Aurora Tech on YouTube.The good:1. Stepper motor is small, lightweight and almost silent. It is tiny in comparison to the stock e stepper.2. Excellent packaging. Everything is in labeled bags and easy to identify.3. When assembled correctly this prints great.4. The actual mechanism seems to be well engineered and looks high quality.5. Tools needed to assemble are included.6. Can be used as both direct drive or bowden tube feed. I have no idea why anyone would want to use anything but direct drive though since that’s the whole point of this upgrade.The not so good:1. Price. This item is expensive for what it is. For $15 more you could buy a micro Swiss all metal hot end kit (of course without any motor).2. Connectivity. There is no wiring connector on the motor like on the stock motor. Instead there is about 20cm of wire that goes to a pair of jumper pins. You then connect these pins to the supplied extension cable which then plugs into the controller board. So this replaces your stock e motor wiring. The bad part of this design is that not only do you have to thread another wire down though the wiring loom, but the jumper pins end up being half way along the wiring loom - so pretty much inaccessible once installed. Also it means you have to remove the access cover to compete the wiring instead of utilizing the existing e motor wiring.Disassembling the unit requires turning the entire motor around to unscrew it from the hot end. That causes the wiring to twist. If there was a connection nearer the motor this wouldn’t be an issue.3. Instructions and vendor contact info: the instructions are stored on GitHub and were ok but definitely poorly translated. Some parts made absolutely no sense. Luckily it is fairly obvious how to assemble. Even worse I was unable to find any direct way to contact the manufacturer. There is no email or company info. That is rather worrying if there is ever an issue in the future.4. The assembly screws down onto your existing hot end. The final orientation of the motor is difficult to adjust and the motor may end up facing the back rather than the front - or at a weird angle as happened once with mine. There is a nut to adjust the position slightly but it isn’t easy to get right.5. Only one long length (about 6cm) of Teflon tube is supplied for inserting into the hot end and cutting. Make a mistake cutting and you are going to need another tube.When I assembled mine I cut it about 0.3mm long so it wouldn’t move around when pulling filament. Unfortunately this caused clogs almost immediately and I had to totally disassemble everything several times before I discovered the tubing had burnt and shrunk causing the clog. In the end I ended up replacing with some blue Capricorn tubing and it seems ok so far. I can’t fault the manufacturer for this problem and hopefully it won’t happen again.6. There is a “free gift” of a 0.4mm nozzle included in the box. But with no information on what type of nozzle this is it is not worthwhile taking the time to try it out. At least they should say what type it is.Summary:This could have been - and for the price SHOULD have been - a lot better. It’s a good start for this designer/company but people expect more for such an expensive upgrade.Things they should improve to make this a better product:1. Cable/connector designThere should be an adapter cable supplied to allow this to connect to the existing extruder motor wiring without having to run a new cable to the controller.2. Include spare Teflon tube. It would cost $0.05 to have included another length.3. Contact info for the company and support. GitHub is not a way to provide support. Vendor says on the page “just send me an email” but there is no email listed.4. More reasonable price. For this price you expect so much more. Sure it is definitely nicely engineered however it is far from perfect.

A**R

Great idea, Poor Support - DON'T BUY

Support is non-existent and now I have an $85 fishing weight. Looks like a great idea, would not work on my Ender 5 Plus with silent board upgrade. Install instructions point to a review channel on YouTube, not from manufacturer. Right after purchase I got an Amazon message from manufacturer about having to swap wires in the plastic connector. No specific instructions for different printers or main boards, just "...if it doesn't work, swap wires in the connector..." I did, and it didn't work. I swapped the other two of the four wires and it didn't work. Support is non-existent, and not too many videos or knowledge on YouTube. Bottom line, it's a fishing weight now and there is no real help available. I'm done with it and moving on to another solution. I will not be buying from this manufacturer again.

S**S

Great concept, poor delivery

Quality control is a problem. Customer service language barrier is not a help either, they do respond quickly though.The drive motor that I received with the D1 unit was dead on delivery. I was hoping it was maybe a driver issue or lack of a TL smoother on my extruder circuit, as it worked one time on my X axis as a test to see where the problem was at. I think it was a fluke as it worked only the one time. After installing the TL Smoother on the extruder circuit, it still did not work, and also failed to work on the X axis.Having gone through all the work removing my printer from the enclosure, accessing the mother board, adjusting the VREF on the driver per the instructions, I opted to at least try one of my pancake NEMA 17 motors on the housing. I really wanted this to work.I got the printer fully assembled and back in my enclosure just to find out the filament grooves that are pressed on the sprocket shafts were not pressed far enough, so the filament was simply going between two smooth wheels.I had to disassemble my hot end again, disassemble the extruder and press the drive wheels farther onto the shafts, then reassemble everything. This should have been a half hour project that turned into 4.I have a bad motor and a modified drive unit so I can not return it in good conscious.Maybe the company will address the quality issues down the road, but I can not recommend this product. It is a great concept, it is very well constructed, but needs more attention to detail.

Trustpilot

2 months ago

2 weeks ago

3 days ago

1 day ago